STM32 HAL Tutorial: Using Timer Interrupts for Responsive Analog-to-PWM Applications

Abstract

Learn how to use STM32 timer interrupts to read ADC values and update PWM output efficiently. Step-by-step guide for responsive sensor-to-actuator control using HAL.

1. Introduction

In previous episodes, we combined ADC readings with PWM to control LEDs or servos.

Now, we’ll make the system interrupt-driven, which:

- Reduces CPU blocking from polling loops

- Provides precise, periodic updates of PWM based on sensor input

- Improves responsiveness in multitasking applications

By the end of this episode, you’ll be able to:

- Configure TIMER interrupt.

- Read ADC values inside its own ISR.

Update PWM output in real-time without blocking the main loop.

2. Prerequisites

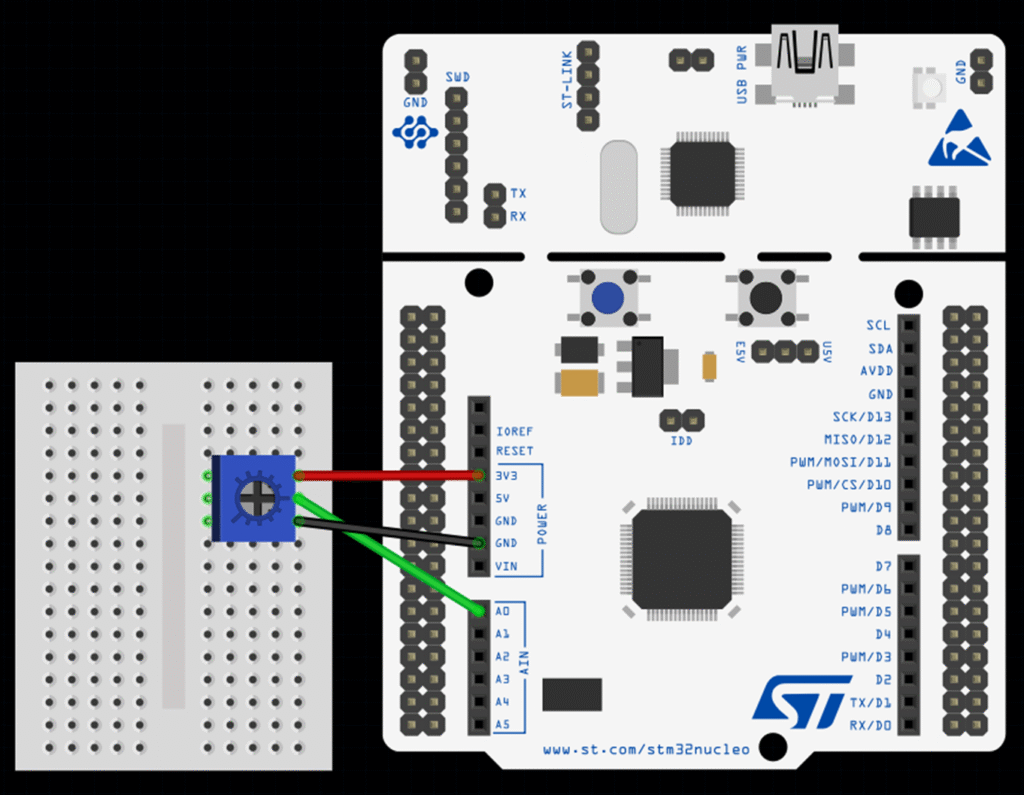

- STM32 board with ADC sensor (e.g., potentiometer)

- PWM output pin connected to LED

- STM32CubeIDE installed

Knowledge of ADC, PWM, and timers from Episodes 5, 9, and 10

This image was made using Fritizing

3. Configuring ADC & TIM in CubeMX

Step 1 – Open Project

- Create a new project in STM32CubeMX.

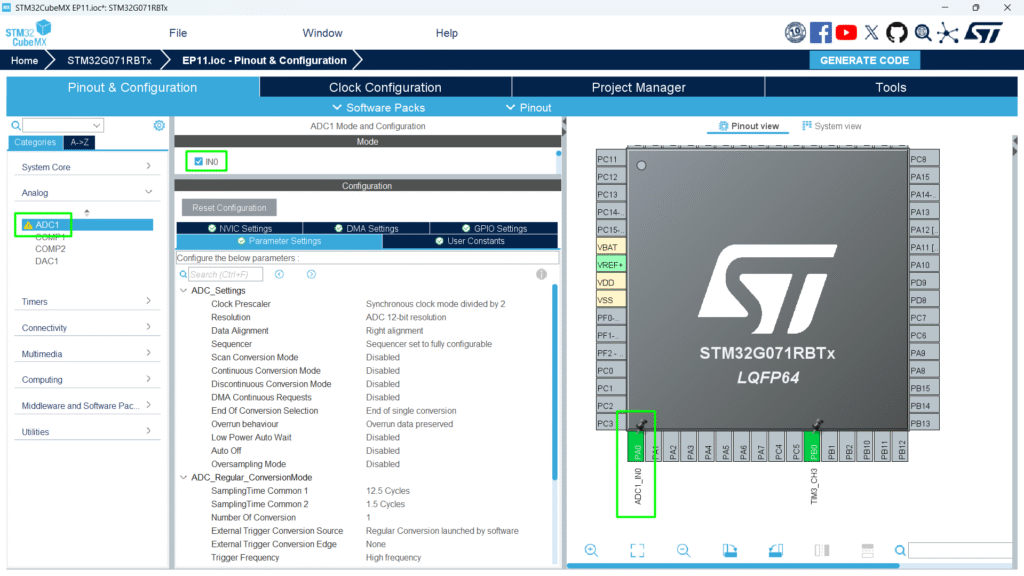

Step 2 – Enable ADC Peripheral

- Go to Pinout & Configuration.

- Select ADC1.

- Assign the analog pin (e.g., PA0) for your sensor.

- Click ADC1 → Parameter Settings:

- Resolution: 12-bit (0–4095 digital values)

- Data Alignment: Right

- Scan Conversion Mode: Disabled (single channel)

- Continuous Conversion Mode: Disabled

- Trigger the conversion in ISR

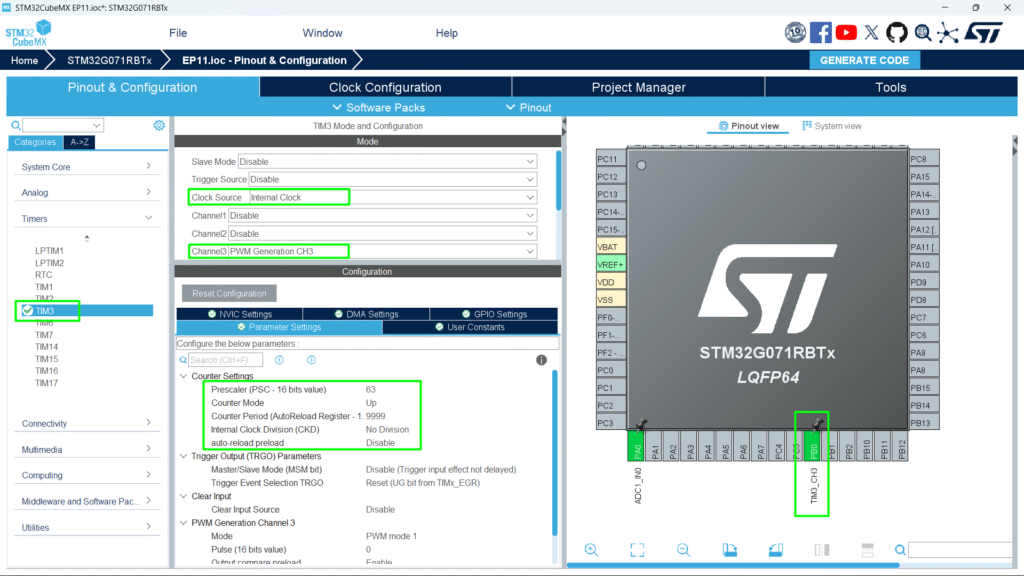

Step 3 – Configure Timer with Interrupt

- Enable TIM3 (or any general-purpose timer).

- Set period to desired ADC sampling interval (e.g., 10 ms for 100 Hz).

- Enable Update Interrupt to trigger HAL_TIM_PeriodElapsedCallback().

Step 3 – Configure PWM Channel

- TIM3_CH3 → PWM output pin (e.g., PB0).

- Set PWM mode and period as in Episode 10.

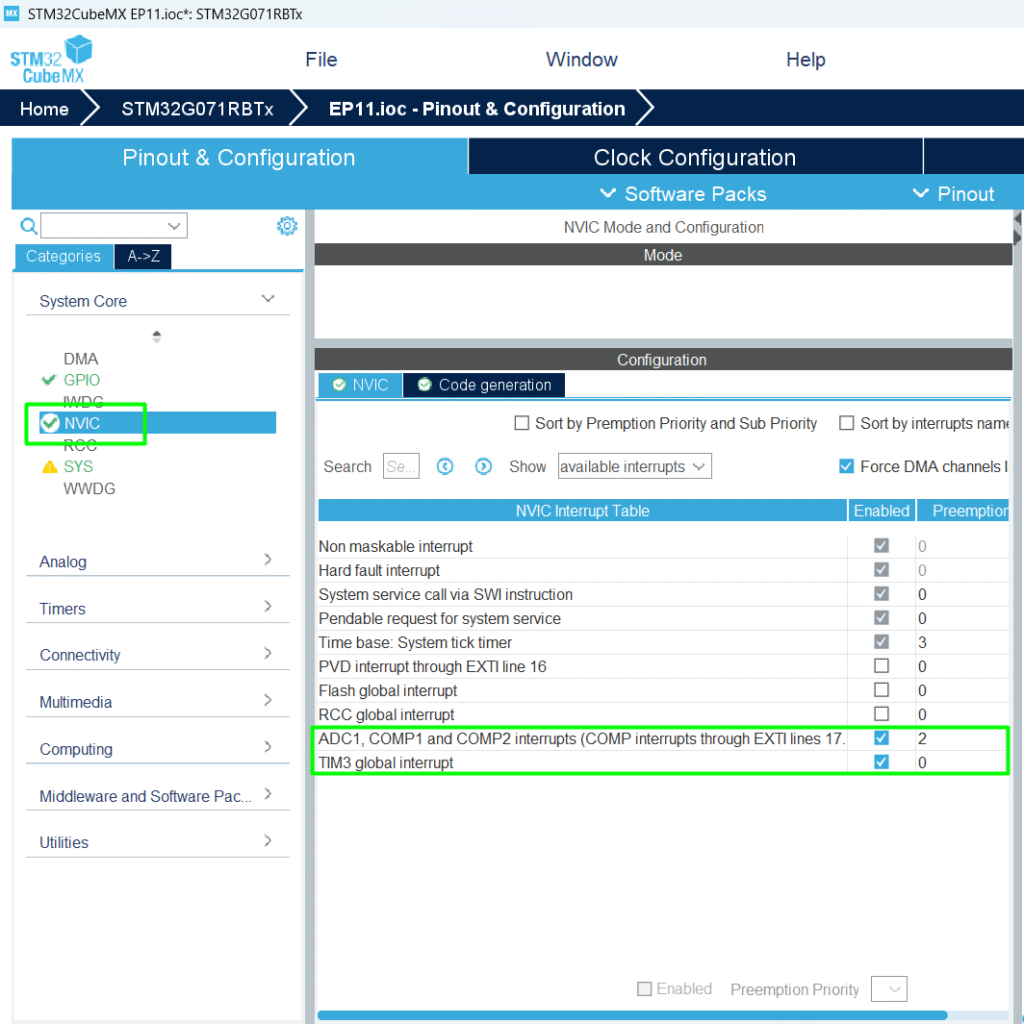

Step 4 – Configure NVIC Priority

- ADC priority level 2

- TIM3 priority level 0

Step 5 – Generate Code

Click Project → Generate Code to initialize HAL ADC structures.

4. Writing the ISRs callback

STM32CubeMX generates a callback function as weak, so the user needs to re-create them:

/* USER CODE BEGIN 4 */

void HAL_ADC_ConvCpltCallback(ADC_HandleTypeDef *hadc)

{

adcValue = HAL_ADC_GetValue(hadc);

}

void HAL_TIM_PeriodElapsedCallback(TIM_HandleTypeDef *htim)

{

// Map ADC value to PWM duty cycle

pwmValue = (adcValue * 9999) / 4095;

// Update PWM output

__HAL_TIM_SET_COMPARE(&htim3, TIM_CHANNEL_3, pwmValue);

HAL_ADC_Start_IT(&hadc1);

}

/* USER CODE END 4 */

Code Explanation

- Timer ISR triggers at fixed intervals (e.g., every 10 ms).

- ADC conversion happens inside its own ISR.

- PWM duty cycle updates immediately, providing smooth control.

- Main loop can remain free for other tasks.

5. Hands-On main code

- The main loop is non-blocking and free.

- PWM output responds to ADC input automatically via interrupt.

/* USER CODE BEGIN PV */

uint32_t adcValue = 0;

uint32_t pwmValue = 0;

/* USER CODE END PV */

/* USER CODE BEGIN 2 */

HAL_ADCEx_Calibration_Start(&hadc1);

HAL_ADC_Start_IT(&hadc1);

HAL_TIM_Base_Start_IT(&htim3);

HAL_TIM_PWM_Start(&htim3, TIM_CHANNEL_3);

/* USER CODE END 2 */

Full Source Code: hackerembedded/STM32_EP11

6. Compiling and Running

- Build Project → Click hammer icon.

- Flash Project → Connect STM32 and run (Ctrl + F11).

- Test PWM Control:

- Rotate potentiometer → LED brightness changes.

- Main loop remains free to handle other tasks (e.g., UART communication, SPI, I²C sensors)

7. Advantages of Interrupt-Driven Approach

- Non-blocking operation → MCU can multitask efficiently

- Precise timing → PWM updates at exact intervals

- Smooth sensor-to-actuator mapping → No lag or flickering

- Scalable → Multiple ADC channels and PWM outputs can be handled in same ISR

8. Common Issues & Fixes

| Issue | Cause | Solution |

|---|---|---|

| LED not responding | Timer interrupt not started | Call HAL_TIM_Base_Start_IT() |

| ADC reading incorrect | Reading inside the wrong ISR | Adjust HAL_ADC_PollForConversion() timeout |

| Main loop blocked | ADC or PWM code outside ISR | Keep main loop free; ISR handles ADC→PWM |

| Main loop blocked | ADC ISR happening too often | Adjust the sampling time and triggering source |